Keeping a roofline watertight is an important part of protecting any home or building. When completing any big project, the fascias and soffits shouldn’t be overlooked, as they form a crucial part of home’s structure. Here at Edge, we believe it is crucial to choose the right fascia material for your client’s needs. Let’s take a look at the pros and cons of choosing either a PVC or timber fascia.

Why a quality roofline is important.

Not only do fascias and soffits give the roofline it’s finished appearance, but they also have a practical purpose too. These boards prevent rainwater and debris from entering the loft space and creating leaks inside the home. While fascias are not required to uphold the structure of the roof, they help to extend its lifespan by providing additional protection against harsh weather. Choosing the right fascias can therefore support the functionality of the rooftiles and guttering.

Looking to source guttering for your project? Check out our great ranges of PVC, steel, and aluminium rainwater systems today.

PVC vs Wood: Durability & Maintenance

Durability is one of the most important factors when sourcing materials for a project. Providing a long-lasting, high-quality finish for your customers is the perfect way to build up those 5-star reviews and become a trusted tradesperson in your local area.

Timber fascias have remained a popular choice as it is a naturally strong material. When well-maintained, timber fascias can last around 20-25 years. However, it is crucial that this maintenance is carried out. Untreated wood will only last around 10 years, and is highly suspectable to weathering, rot, and splintering. If your customer wants to ‘fit and forget’, then wooden fascias are not the best choice.

PVC is a strong and durable material, making it a great choice for roofline products. While PVC can sometimes initially cost more than timber boards, the PVC fascias do not require painting, staining or sealing. This means that there are no further costs associated with these boards, and they will last for approximately 20-30 years. All the homeowners will need to do is give the boards a clean yearly to keep them looking their best.

PVC vs Wood: Style and Customisation Options

Homeowners, whether commissioning a new build or undertaking a home renovation project, are always looking to create a stylish yet practical house. While images of fascias and soffits may not be at the top of their Pinterest boards, we know that the right finish can complete a home.

Wooden fascias and soffits offer a classic look to a home, especially one with more classic features. Period properties in particularly often benefit from the look of wooden fascias. Alternatively, they can blend seamlessly into cabins and other wooden structures. These timber boards can also be painted to suit the colour palette of the house.

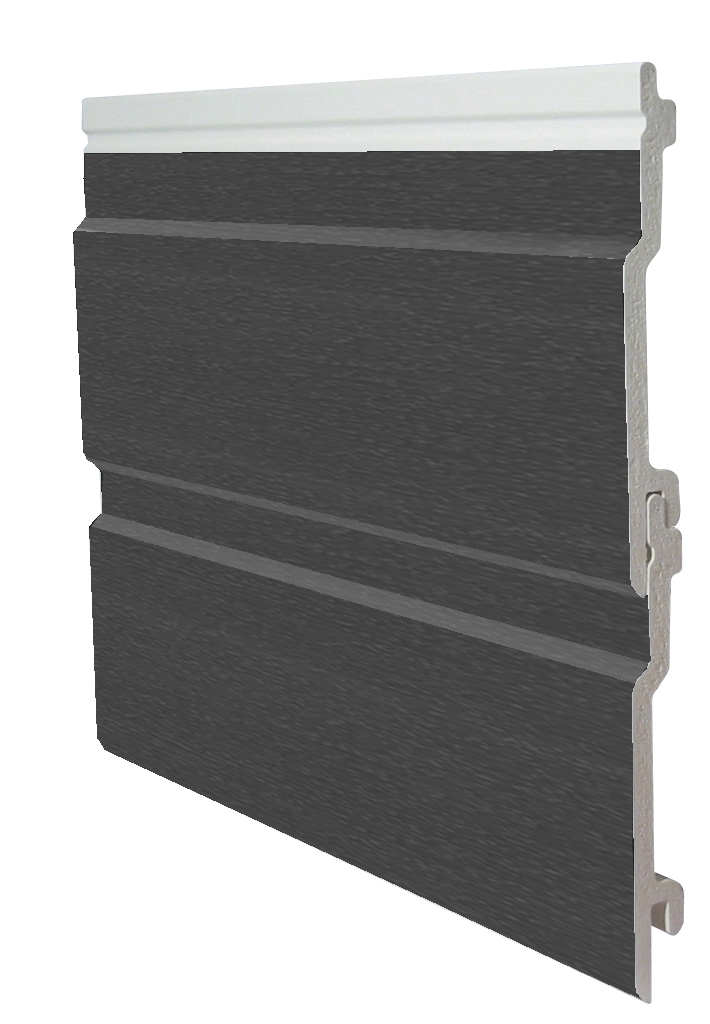

However, with a PVC fascias customers can select the exact finish of wood they love and still enjoy all the benefits of a PVC product. From foiled boards to dyed plastics, there is a wealth of choice available to customers looking to renovate their home. Here at Edge, we offer fascias in 15 different colours and in 4 different finishes. Homeowners can enjoy the classic beauty of a Rosewood or Irish Oak fascia without needing to seal, paint, or check it for wood-rot. PVC fascias offer the best in both customisation and reliability.

Looking for a unique colour or finish? Call us on 0345 021 3333 and we’ll be happy to help you source the fascias you need.

PVC vs Wood: Sustainability & Environmental Impact

As a builder or contractor, it is important to make sure that the materials you are purchasing are sustainable or come from sustainable sources. Often, this means making sure that the product can be properly recycled or disposed of at the end of its life.

Distributers of wooden products should make the environmental accreditation of the wood clear and indicate whether it has come from a sustainable source. As wood is a naturally occurring, it is arguably a sustainable and environmentally friendly building material when cultivated in a responsible way. Damaged or rotting wood can also be disposed of in green waste to decay naturally.

Manufacturers of PVC should also make it clear what their environmental policy is. The great lifespan of PVC products, and the fact that no additional chemicals are required to maintain the boards, does increase its sustainability. PVC products should be responsibility recycled at the end of their use to ensure that no unnecessary waste is being sent to landfill.

Final Verdict…

Although timber fascias do play an important role in some construction projects, here at Edge we believe that PVC is best choice for most homeowners and commercial properties. This is because unlike wooden beams, PVC fascias are lightweight and easy to install. Plus, once they have been installed, they only require a wipe with soapy water to stay looking their best. PVC offers the best in terms of colour and style options, mimicking the look of classic wooden beams while offering a low maintenance finish.

To find out more about our great range of fascias and soffits, and to place your next order, get in touch by emailing [email protected] or call 0345 021 3333. Our three trade counters are well-stocked with both fascias and soffits, as well as the required fascia accessories such as corners and joints. Let us take care of the roofline for you with our trusted service and reliable deliveries.

First published in 2022. Updated for 2025.

Freefoam’s diverse cladding range is a popular choice for long-term stockist Edge Building Products and its customers. The company has seen a robust increase in sales of Freefoam’s products over the past four years.

Edge Building Products was established more than 25 years ago and sells a wide range of low-maintenance building products across its three branches. It added Freefoam’s cladding range to its offering in 2017, in response to customer demand for a greater range of colours in the cladding market.

Edge Building Products Managing Director Kieran Napthine rates Freefoam’s cladding range, colours and product innovation as “excellent”. He says: “We were attracted to Freefoam’s Fortex range because of its diverse colour options and the excellent range of trims that are included in the system. From our customer sales, we see the strongest demand for grey colours.

“The system is so easy to use and install. It is easy to cut, and handles much better than fibre cement products, which have a similar appearance.

Since Freefoam’s introduction, sales of the brand’s products have been growing for Edge Building Products. This is, in part, due to the expanding home improvement market, which has been going from strength to strength.

Edge Building Products mostly supplies Freefoam cladding products to builders, homeowners, for home improvement projects, and double-glazing companies. It has also supplied several new build properties, with excellent results.

Kieran says: “We have definitely seen an uptick in home improvements over the past year. We believe many people are investing funds they would normally allocate to holidays and hospitality to improve their homes.

“The ‘New England’ style is very popular with homeowners, particularly in the South, and Freefoam’s Fortex cladding range is a great fit for this style of property. It provides a cost-effective, low-maintenance option for anyone looking to make long-lasting, attractive changes to their property.”

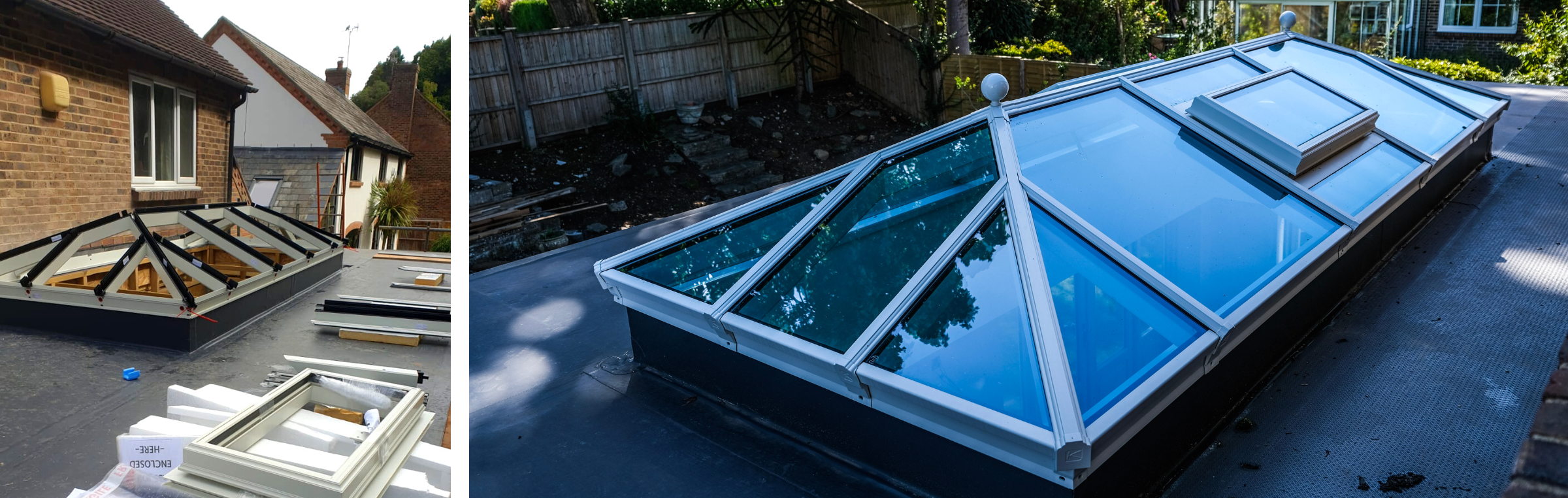

Our September Installation of the Month Award goes to Russell Harding and his fantastic renovation of this beautiful family home in West Sussex. The project involved a single-storey orangery style extension, including installation of a stylish roof glazing system and decorative fascia boards to give this property a fantastic renovation.

The large white aluminium EdgeSky roof lantern, brings a feeling of space and light into the expansive new space. Two manually opening vents help with temperature control and air-flow, whilst the external ball finials give this contemporary glazing system a more traditional feel, which is in keeping with the overall property style.

Ogee fascia was installed into the project to give the roofline a more decorative and ornate finish. Matching the colour of the timber french doors, this beautiful fascia also compliments the style of the overall property.

So, we’d like to say a huge congratulations to Russell Harding Carpentry, for this fantastic project. We look forward to seeing more of his work in the future.

There are quite a few types of cladding design, and many different ways to install them – but, like most traditional building supplies and methods, there must have been a practical reason behind each design and installation technique when it was invented. In this blog, we’ll explore the history of shiplap cladding and delve into our own cladding range at Edge.

What is Shiplap cladding?

Shiplap cladding is a traditional cladding design with a smooth or woodgrain finish, installed with and an overlapping or interlocking edge detail, producing a watertight façade. What differentiates shiplap cladding from other cladding types is a wide scoop-like ridge on the top edge of each board instead of a shadow gap, which both open V and tongue and grove cladding have.

History and Origin

What was shiplap originally used for?

Shiplap, as the name suggests, was originally used to build the sides of a ship. In fact, it is suggested that it was used incredibly early on in naval architecture, due to its waterproof and resilient qualities. The Viking ships that invaded Europe are said to have been clinker built, (boat building using shiplap techniques) and so were the ships that William the Conqueror used to invade Britain in the 11th century.

An ancient boat (dates from around AD 300) is said to have been found in Als, Denmark more than 100 years ago and is the earliest discovered example of clinker construction that uses overlapping planks, which were then called lapstrakes. These were a precursor to shiplap cladding, but they created a watertight seal and were installed using the same techniques as shiplap cladding is today.

It’s pretty obvious now that shiplap weatherboard cladding is used on our homes to protect them from rainfall and other damaging weather conditions. Although, these days cladding is often chosen for the sole purpose of improving the aesthetics of a property – it still plays a major part in defending our homes against the elements.

Where is best to install shiplap cladding?

Shiplap cladding can be installed almost anywhere. It is ideal for installing on house exteriors, garden sheds and outbuildings, schools, beach huts, holiday homes and commercial or industrial buildings. Whilst it is normally installed horizontally, there are ways to install shiplap vertically too.

Our shiplap Range

Our robust PVC shiplap cladding profiles are made to suit traditional styles, but with complementary joints, trims, and fixings. Cellular PVC cladding is an ideal alternative for timber cladding as it will not discolour, it retains its appearance, is virtually maintenance free and is weather resistant.

Fortex Range

Our Fortex cladding products combine an authentic painted timber grained look with the low maintenance benefits of PVC.

-

- Durable – Fortex cladding products are made from an environmentally friendly lead-free formulation and is guaranteed for 10 years

-

- Light & Easy to Install – With the Fortex system, storing, handling, and fitting is very simple and easy. Its light weight offers many benefits over fibre cement cladding products, in fact at 3.15kg per 5m length it is 4 times lighter than a comparable fibre cement board!

We also have a comprehensive range of cladding trims available to suit the Fortex boards ensures a neat and professional finish whatever the application.

Use our handy visualiser tool to choose your cladding colour

You can calculate your cladding requirements by clicking this link: https://edgebp.co.uk/fortex-cladding-calculator.

Make sure you check out the Fortex videos on our YouTube channel too!

Fibre cement

The ultimate alternative to wood, our Hardie plank cladding range is made from resilient, maintenance-free fibre cement. Giving your customers all of the benefits of a stylish wooden façade with none of the hassle. Made from natural materials this product provides strength, durability, and protection. It is also available in a wide range of colours to give your project the perfect finish.

Download our Hardie plank brochure

James Hardie fibre cement is thinner and lighter-weight, yet stronger and easier to handle than most alternative building materials, ensuring your build moves along faster – with less hold ups and complications.

-

- Low maintenance

-

- Weather resistant – doesn’t shrink, crack or warp

-

- Fire resistant – non-combustible A2 fire rated

-

- Lightweight for easy installation

-

- Eco-friendly

-

- Composed of Portland cement, sand, cellulose fibre, water, selected additives

Use the Hardie online calculator and visualiser and check out the HardiePlank installation video!

Need more information?

We’ve got other blogs about our cladding range, check them out!

Or, you can give us a call on 03450213333 or pop an email over to [email protected] and we’ll be able to help you.

We are delighted to announce our first Installer of the Month for their contemporary and innovative new build development in Midhurst, West Sussex – King and Drury Construction.

Installer of the Month is a new initiative which recognises and celebrates inspirational and forward-thinking projects which our customers have been working on.

In April, King and Drury were selected as deserving of the title. Their West Sussex project was a 12 month collaborative design process between MH Architects and the Southdowns National Park, which resulted in 4 striking townhouses. The properties are a showcase of contemporary design, within a traditional location – celebrating the architectural language of our time with sharp zinc roofs and angular shaped glazing.

We were lucky enough to supply aluminium windows, doors and bi-folds in Pale Brown (RAL colour 8025), which King & Drury installed to perfection. It’s fantastic to see how these glazing designs have been used to style the property whilst simultaneously creating an area of light, airy space internally.

Founded by James King and James Drury, King and Drury are award-winning property developers known for building high-end homes in hand-picked locations. We’re delighted to award Installer of the Month to this fantastic, progressive business and look forward to supplying for their projects in the future.

Government restrictions are starting to ease but the construction sector is still feeling the effects of the pandemic.

With the home improvement market booming after a year of reduced consumer spend, home owners have saved on meals out and holidays abroad, which means they are able to embark on those renovation projects they have been putting off. However, the demand fuelled by the booming domestic housing market, coupled with COVID and Brexit related materials delays, means prices are increasing and the supply chain is under more pressure than ever before.

Retailers are adapting to these unprecedented market conditions and are working hard to support their customers as best they can. South-East based business Edge Building Products are no exception. They have tackled the materials shortage by increasing order volumes and holding more products in-stock to avoid those longer lead times. They are committed to supporting their customer’s businesses and refining their buying strategy to meet the demand.

Kieran Napthine, Managing Director at Edge Building Products says, “The demand in the home improvement sector is fantastic. We’re seeing growth across all of our lines and the business is growing as a result, but we’ve had to adapt to this new market quickly to ensure we can still access the products we need.”

He continued, “Our main focus is the customer, and supporting their business. If the trade can’t get access to the products and materials they need, they can’t complete their project on time, which reflects poorly on their business.”

“To give our customers more confidence, we have reviewed our buying strategy and now hold more products in-stock to avoid long lead times. On top of this, we’ve invested more in marketing, to make sure our products are accessible and visible to new customers struggling to access the materials they need.”

“We know this year is going to continue to be a challenging one, as demand continues to surge and material prices increase, but we’re doing our very best to remain competitively priced and maintain high stock levels with as little disruption to our customers as possible”.

Cladding is a great way to bring character to the exterior of any project. Whether your customer is looking to create a seaside look, Scandinavian hygge or contemporary style; cladding is compatible with most designs.

With a surge in demand for home offices, summer house construction and home renovation – requests for external cladding have rocketed. People are spending more time at home, with more money in their pockets after not paying out for holidays and entertainment for over a year. Home improvements are at the top of the homeowners agenda, with many stating that they will be staying at home long after lockdown has eased.

What are the benefits of external cladding?

Cladding is a low maintenance, external styling solution. Its durability provides protection from the elements, whilst making buildings more resistant to defects caused by rainfall, sunlight and temperature change. Cladding also improves the structural strength of the building.

What type of cladding does Edge Building Products sell?

Edge Building Products holds a vast range of external shiplap and open V cladding systems. From PVC Fortex cladding, to Cembrit – Fibre cement cladding – there will be something to suit your project. Edge also supplies the cladding trims, necessary installation tools and guides, with a great team of customer service staff that are on hand with advice.

The cladding crisis, which stemmed from the tragic Grenfell Tower fire in 2017, means building control are anxious to ensure that all buildings are cladded with safe, fire resistant or non-combustible cladding. Edge Building Products supplies the non-combustible Cembrit Fibre cement cladding, Fire Rating Class A2 – while the Fortex cladding range has been tested to EN 13501-1, achieving D, S3 and D2 fire rating.

Need help with the cladding for your project?

We have some handy cladding tools on our website, which you might find useful.

Head over to our Fortex cladding visualiser to see what different colours will look like. Or use our cladding calculator to find out how much cladding you need to order.

We’re delighted to award our June Installation of the Month to Dowling Carpentry and Construction Ltd for their contemporary residential new build project.

This Sussex development represents progressive innovation in residential construction, leading the way in modern architectural design. Angular, two storey glazing and dormer windows characterise this unique property, giving it a light and airy feel.

We supplied bespoke, dark grey windows and doors in smart profile, plus roofline products for this fantastic project. Large format glazing is becoming incresingly common as homeowners strive to create unobstructed views and connections between internal spaces and the surrounding landscape. Dowling Carpentry and Construction Ltd have utilised large format glazing perfectly in this Emsworth property, creating space, light and style.

Congratulations again for such a fabulous development. We look forward to seeing more of your work in the future.

An Overview

At Edge Building Products, our EDGEsky rooflight range comprises aluminium roof lanterns and flat glass rooflights. These come in a range of stocked sizes and can also be made to measure – with standard and special colour options.

Why choose Edgesky Rooflights?

One of the main benefits of having rooflights is the incredible amount of natural light they bring into a space. Not only does this make the space more appealing – bringing out the true colours of internal décor – it also can save on electricity costs for lighting.

Benefits of Flat Glass Rooflights

-

- Very easy to install, comes as it is, with no ‘extra bits’ needed

-

- Thermally broken aluminium frame, with an overall U Value of 1.3 w/m2k

-

- Minimal sightlines

-

- Sleek design

-

- Stands 63mm above the upstand

-

- Laminated, shatterproof glass

-

- High-security performance

Benefits of Roof Lanterns

-

- Simple installation

-

- Great aesthetics, a traditional style with a modern twist.

-

- Thermally broken eaves beam, maximising thermal efficiency

-

- Hidden fixings, allowing an uninterrupted, sleek design

-

- Subtle ogee detailing, bringing out an elegant, classic feel.

-

- Supplied with a range of high-quality self-cleaning glass choices

-

- Slim roof bars, only 57mm wide

Styles complemented by Flat Glass Roof Lights

Our flat glass rooflight design is very minimal, and we find that it suits the more contemporary spaces. We have seen some great installations of these in art-deco style properties, sometimes in a dining room, bringing masses of natural light to the table (literally), or in a bedroom – acting as a window to the stars. This rooflight is so simplistic and versatile; you’ll find that it can work in most spaces, whatever the style!

Where to put a lantern rooflight

A roof lantern skylight is an ideal statement for a traditional-style space. The option to add finials and extra bars to the frame brings a classic dimension, and, when installed on a flat roof, can make a massive difference to the exterior character of your property. However, a slimmer framed lantern and no finials will give you a more contemporary feel, bringing some minimalist structure to your roof. We like to think of roof lanterns as a conservatory roof, without so much heat loss – bringing in plenty of natural light, but without the conservatory sides creating a less thermally efficient space.

Which rooflight is best for you?

So, to round it up – our range of rooflights will easily cover your style and practical needs. For the minimal, modern look; check out our flat glass rooflights. If you are going for a traditional, classic look – our lantern rooflights are just what you need. If you’re still not sure which one would be the best choice, feel free to get in touch with our team. We’re happy to provide you with further information on our Edgesky products that could help you to choose the perfect rooflight.

Home renovation during covid has been one of the main go-to occupations for residents stuck in their homes. Here, we cover the most popular home improvement trends that we’ve seen and supplied.

1. The Home Office

The number one trend we’ve observed is the home office. Many people who have said they will not be going back into the office in the long term have built office rooms in their gardens to get away from the main house and its distractions during the working day. This, in turn, has left the original indoor study spaces vacant, as devices and office essentials move outdoors. Residents make the most of these spaces that have been vacated indoors, often by creating extra lounging areas or creative zones in the home.

2. Home extensions

Next up, we have found that home extensions are becoming more and more frequent. Again, due to covid keeping us all in our homes, the need to create more space to live in has been at the forefront of our minds. We are loving the extension photographed below; with the fantastic flush casement windows and doors and classic coving.

3. Garages

Another of the latest home renovation trends is a garage conversion. With leisure and entertainment being closed in the last few months, many homeowners have converted their garages into gyms, bars, cinemas and studios.

4. Loft conversions

People that don’t have much garden space for extensions may go for the loft conversion project. These are a great way of adding another bedroom or some more storage space to the property and is said to add up to 20% to the value of a home.

5. Refurbishments

Having a little more time on our hands while being at home has made us aware of the need for improvement in some areas. Whether it’s a bit of chipped paint, a run-down patio, or some rotting wooden windows – most people have found fault somewhere. Some chose to change the glazing in their houses as having new windows fitted can change the whole look of the property. Others want to change the whole frontage of their homes, using cladding or paint. We have also noticed that many homeowners have been improving their gardens, especially outdoor eating areas, by installing decking and outdoor kitchens. We really liked the refurbishment project photographed below, with our Fortex cladding, fascias, soffits and Liniar windows.

What’s your next project?

The home improvements market has rocketed over the last few months. Homeowners are clearly making more of an effort to neaten up their properties and create larger living spaces – making them more enjoyable to live in. People have also had more time to put their home renovation ideas to practice, giving them a project to occupy them during lockdown periods.

This month we’re awarding Harvey Works our July Installation of the Month for their fantastic West Sussex renovation project.

Danny Harvey and his team have developed this single-story, older retirement property into a modern, stylish two-story family home.

Situated on a private road just outside Chichester, large aluminium bi-fold doors and a rooflight lantern have been used to create a feeling of light and space in the large open-plan living space at the back of this property.

Contemporary stairs ascend in the middle of this stylish home, which cleverly separate the kitchen from the living space, whilst retaining an open and spacious feel.

Grey pvc windows and doors have been expertly installed for the perfect finish, contrasting against the crisp white walls and lighter grey cladding that wraps around the top half of the house.

This development is a great example of how older properties can be completely transformed to cater for a young family. It also showcases the Edge bespoke range of windows and doors perfectly. Congratulations to Harvey Works for receiving this award and we look forward to seeing more of your work in the future.

What is cladding?

Cladding is the process of applying one material onto another material to create an external skin or layer. Available in a variety of sizes, colours and surface finishes, cladding is a popular product for anyone who wants to take the look of their building to the next level.

Why is cladding used?

Typically, cladding is used to improve the appearance of a building. It can also bolster the weather resistance of a building or act as thermal insulation.

Other uses for cladding a building that are often overlooked are sound-proofing and fire safety. If a building is designed to stop sound from escaping it, for example a music studio – installing cladding on outside of the building gives it an extra ‘skin’, making it harder for sound to escape.

Fire safety has become an important issue in the cladding industry, following the tragic Grenfell Tower fire disaster. Many cladded buildings (residential buildings over 18 metres in height) are now under review as to whether the cladding is fire proof – and if not, it has to be removed and replaced with a fire resistant type; such as fibre cement cladding.

What are the different types of cladding?

There are many different types of cladding boards, with each material offering various looks as well as a range of properties. Cladding boards can be either horizontal or vertical, meaning you can achieve unique and striking designs.

Here at Edge, we provide a vast range of cladding systems that are easy to install and have many colour and style options.

Shiplap cladding

Our range of shiplap cladding is designed to overlay in such a way that there is a flat surface overall. This improves its weather resistance by allowing any water to run off the boards and minimising draughts.

Open V cladding

The Open V cladding range is a common preference for those looking for a unique open v appearance. Sometimes referred to as ‘tongue and groove’, our open V cladding is 100mm wide and comes with a wide range of trims and accessories to ensure a perfect installation, every time.

Fortex cladding

A great combination of an authentic painted timber grained look with the low maintenance benefits of PVC.

Durable – Fortex cladding products are made from an environmentally friendly lead-free formulation and is guaranteed for 10 years (T & Cs apply).

Light & Easy to Install – With the Fortex system, storing, handling, and fitting is very simple and easy. Its light weight offers many benefits over fibre cement cladding products, in fact at 3.15kg per 5m length it is 4 times lighter than a comparable fibre cement board!

PVC cladding trims

We have a large range of PVC cladding trims, in many colours, to match your cladding choices. These are also suited to the different cladding styles we offer.

Fibre cement cladding

The ultimate alternative to wood, Cembrit plank cladding is made from resilient, maintenance-free fibre cement. Giving your customers all of the benefits of a stylish wooden façade with none of the hassle. Made from natural materials this product provides strength, durability and protection. It is also available in a wide range of colours to give your project the perfect finish.

For more information, view our brochure on fibre cement cladding.

Which cladding is best for your building?

Choosing to clad a building is a big choice, so it’s good to take your time and make sure you go for the right material. It can alter the look and feel of your building and also provide economical benefits by keeping in heat.

If you’re still not sure, feel free to give us a call and speak with a member of our team. Based in Croydon, Chichester and Horsham, we stock a range of building products, including a wide range of external cladding and decking. We’re happy to help and provide you with further information to make sure you choose the right cladding for your building.

What is composite decking?

Composite decking is a man-made building product that is manufactured from a unique combination of sustainably farmed wood-fibres and recycled plastic. Composite decking keeps its look and feel for far longer than timber, with substantially less maintenance. The range at Edge Building Products is available in a range of colours and has two options of composite deck board, both available on short lead times.

Where else are composite materials used?

Composite decking boards and tiles are versatile building materials that can be used in a wide variety of external features such as doors, cladding and architectural mouldings. The various compositions of composite materials allow products to be tailored to meet the needs of different market areas such as home extensions, renovations, new build properties and refurbishments. This approach to usage of composite materials, was originally taken up by the US – but very quickly, the UK markets followed suit, with the first domestic FRP (fibre-reinforced polymer) doors introduced around 15-20 years ago.

What are the benefits of composite decking?

There are many benefits of composite decking, which explains why they have quickly become such a popular alternative to traditional decking materials.

Long-life decking

There’s no point in building something unless it’s going to stand the test of time. Composite decking has a long life and is constructed to go the distance. Whether they are installed in a harsh or risky environment, the composite materials are durable and resistant; able to withstand high pressure situations, blasts and fire resistance. Our composite decking range also includes all of the necessary accessories, to ensure a perfectly finished installation.

Less maintenance, more quality

With traditional decking, splitting, cracking and rotting wood is always a very real threat. Composite decking boards mean you will have a longer-lasting product that is still high quality. You may pick up a composite decking board and be surprised at its lightness in weight, but this is not an indication of poor quality. Our decking boards have been carefully designed so that they are easily handled, saving time on site by not having heavy weights to shift and install.

A distinct and appealing look

The composite decking boards we offer provide a unique and beautiful look. Their resistance to weathering and other minor defects like cracks and fade marks keep them in top condition. Our signature capped wood-polymer composite (WPC) decking boards have a timeless wood-grain appearance, for the look of wood without any of the downsides of timber decking. Engineered with a plastic cap, signature boards boast the maximum possible durability, with protection from expansion, fading and staining. The signature boards have a different colour on each side which means you can use one product to create a contrasting effect if required. Teak & mahogany are on one board and silver birch and ebony on the other.

Our signature capped wood-polymer composite (WPC) decking boards have a timeless wood-grain appearance, for the look of wood without any of the downsides of timber decking. Engineered with a plastic cap, signature boards boast the maximum possible durability, with protection from expansion, fading and staining. The signature boards have a different colour on each side which means you can use one product to create a contrasting effect if required. Teak & mahogany are on one board and silver birch and ebony on the other.

Our classic wood-polymer composite (WPC) decking boards have a contemporary, grooved appearance, for that quintessential composite look. The boards are also reversible, offering greater design possibilities.

Thinking about choosing composite decking?

If you’d like to benefit from low maintenance decking and still enjoy an authentic look, then choosing a composite material is the way to go. We have a range of colours, from grey composite decking through to different shades of brown. Based in Chichester, Horsham and Croydon, we stock composite decking and an extensive range of building products. If you have any further questions about our products, feel free to email us at [email protected] and speak with a member of our team. We’re happy to help you and provide you with further information.

What are composite doors?

Secure. Durable.

Unlike uPVC doors, which are made of just plastic, a composite door is made from a combination of materials that are compressed under high-pressure conditions. This makes the door thicker and stronger and of better quality. At Edge, our external composite door range comes with a large range of style and colour options.

The pros of composite doors

Secure

Composite doors offer better protection than any other material you might be contemplating for your new doors thanks to their resilience.

Stylish

The style and design of your new door are sure to be of high quality – composite doors are a wonderful choice as there’s a broad variety of colours and styles to suit any property. Those who love the look of a wooden door will be pleased to know that you can achieve the traditional style with a composite door. It’s sometimes hard to tell the difference between composite and wooden doors!

Trouble-free

Composite doors don’t require much upkeep, the occasional wipe down and drop of oil on the hinges every now and then is pretty much all that is needed to keep your door functioning perfectly.

The cons of composite doors

Price

Composite doors tend to be more expensive than uPVC doors, however, the two products have their different advantages. We find that composite doors can always be relied upon for security, and quality finish.

The picture above shows one of our recent projects. Our composite front doors are always popular; we love how this one really centralises the smart exterior of the property and completes the contemporary style. To find out more about our full range of composite doors, speak with a member of our team today. We’re happy to talk you through our range of products and help find the perfect door for your property.

Over the past 40 years, Smart Architectural Aluminium has grown to become the UK’s leading supplier of aluminium systems, building a reputation for high quality, innovative and well-designed products constructed with technical expertise.

Alitherm 300

The Alitherm 300 series, the most popular range at Edge Building Products, offers a selection of high-quality glazing solutions for side and top hung open out windows suitable for both residential and commercial projects. It can create traditional casement windows inspired by the elegance and styling of timber products, or modern style windows designed for modern homes or offices.

Alitherm products are available in a choice of standard or non-standard colours, including metallic, dual colour, Smart’s Sensations textured, and Alchemy anodised effect finishes.

British Standard Kitemarked system KM 81580 KM 81543

The system features an extended polyamide thermal break which improves the overall U Value of the profile, allowing Alitherm 300 to achieve a Window Energy ‘A’ Rating when used in with the correct double or triple glazed unit.

-

- The system is suitable for both internally or externally beaded, side or top hung open out windows

-

- Profiles have the option of either ovolo, chamfered or square edges

-

- Frame options for both standard and slim-line stays

-

- Option of either multi-point or cockspur locking handle

Smart Aluminium Extrusions | The Company

With over 30 years of experience, Smart Aluminium Extrusions (SAE) has grown to become the UK’s most modern and efficient manufacturer of extruded aluminium profiles.

SAE are part of the global Corialis Group of extrusion companies that has its headquarters in Belgium and manufacturing plants in France, Poland and China. Employing over 1,500 people worldwide and with a turnover in excess of £250 million, the group’s success is underpinned both by exceptional research, development facilities and state-of-the-art manufacturing resources. If required, SAE can draw on the wealth of expertise and experience within the group to meet specific customer needs.

The fantastic photo above is of a project we supplied. The bi-folds are in Smart profile, coated with a special RAL colour!

Another great project where we supplied aluminium windows, doors, glazing, bifold sliding doors and apex frames; all in the Smarts profile.

Smart aluminium front doors

The Smart front doors are of excellent quality, successfully blending style, performance and security. Manufactured by experienced hands, there is a door design suited to everyone.

Not just ‘any old’ front door

First Class Security

Only the best quality security fittings ensure that your new door has exceptional levels of protection.

Precisely Constructed

With care from high-quality aluminium, our expert craftsmen build each door to your bespoke requirements.

Thermally Efficient

These doors are fully insulated to prevent heat loss and reduce energy consumption in your home.

Get the Smart Aluminium experience

Whether you’re looking for aluminium doors or window glazing, Smart Aluminium Systems can provide you with an excellent range of products. With years of industry experience, their portfolio of products is both extensive and high-quality.

Get in touch with our team today to find out more about Smart Aluminium products and how they can fit into your project.

This month we’re awarding Brad Coe, from Aurora Glazing, Installation of the Month for his fantastic work at the beautiful Tinwood Vineyard Estate, located on the outskirts of Chichester, West Sussex.

Brad and his team installed huge Origin bi-folds (8.8 x 2.7m) and large sliding doors (3.4 x 2.7m) in anthracite grey, into the contemporary tasting room of this popular vineyard.

This stunning premises, set in the picturesque location of the South Downs, became a vineyard back in 2007, when the owners (Jody and Art Tukker) planted their first vines. They had to wait until 2009 before they had their first small crop and in 2010 they saw their first commercial harvest. In 2013, a small tasting room was built, which was developed into a larger tasting room in 2019 that enabled them to hold tasting sessions of 30-40 people.

Inspired by a winery in South African (Ernie Els) and multiple Australian vineyards, Art was keen to create an open and contemporary tasting room, which welcomed people into the vineyard. Large expansive bi-fold doors were the perfect solution to achieving space and light, allowing one side of the property to be completely opened.

Art said: “Our tasting room, with the wood and the glass tells people that we’re very open, and there are no secrets. You don’t need to wear a suit and tie. You can come in your shorts and wear your jandals [flip flops]. Having a modern tasting room and making those connections is really important.”

Shortlisted for a RIBA regional award, this beautiful tasting room is recognised as a step-change in modern architecture, which demonstrates how large bi-folds can be used to create space, light and openness in a property.

In additional to the tasting room, Brad also installed bifolds, residential doors and flush casement aluminium windows into the owner’s family home, situated next to the vineyard. Much like the tasting room, this stylish property combines natural materials (wood) with urban style (concrete) for the perfect contemporary architectural design.

Well done to Brad for such a fantastic installation, we look forward to seeing more of your work in the future.

A bit of background knowledge

Origin was established in 2002 by cousins – Neil Ginger and Victoria Brocklesby, after their discovery of a gap in the market in the UK for high-quality bi-fold doors. Since then, Origin has progressed with their excellent designs and manufacturing, and now offer aluminium windows with the same elegance and quality as their aluminium sliding doors and bifold doors.

Above is Origin’s Premium Window (OW-80)

“Quite simply, our vision is to transform the way families enjoy their home – from inside to out”

So where does Edge come into this?

Edge Building Products became one of Origin’s premium partners in 2021, we are trained in product knowledge and installation (although we only supply Origin products, we can recommend Origin-trained installers). We always find that the Origin products are flawless, and unique in their superior quality. If you would like to come and see them for yourself, we have samples in our Chichester Showroom

Suited to any property

Origin products are completely bespoke and tailored to your needs. Whether you are looking for a contemporary style, traditional charm, or even a marine graded product for a seafront property, you are guaranteed to find a product that matches your requirements.

Origin’s door range

-

- Sliding Doors

-

- Bi-fold Doors

-

- Corner Doors

-

- Single Doors

-

- French Doors

-

- Front Doors

-

- Garage Doors

Origin’s Window Range

-

- Casement

-

- Fixed Frame

-

- Bay Windows

-

- Gables

-

- French Casements

-

- Bi-fold Windows

About Soudal

Founded in 1966, Soudal is the biggest independent (EU) manufacturer of sealants, adhesives and polyurethane foams for both trade and end users. This Belgian family-run company based in Turnhout has developed into an international player and expert in chemical construction specialities.

Soudal Products

Soudal manufactures silicones and other sealants, polyurethane foams (PU foams), adhesives, hybrid polymers, technical aerosols and chemical building products. This extensive range of products means they provide solutions for many industries, workplaces and projects. All products are tried and tested by highly qualified engineers, researchers and technical experts, expanding the strength and ease of use of all Soudal products. As Soudal products are so widely used, making sure they are consistently manufactured to a high standard is an essential part of Soudal’s production process.

Our Soudal range here at Edge Building Products

At Edge, we supply a vast range of soudal products, including but not limited to: silicones, fillers, fix-all adhesive, expanding foams and plenty of Soudal cleaning products.

Soudal ‘in situ’

There is hardly a home improvement project that wouldn’t benefit from at least one of the Soudal products. Whether you are bonding items together, sealing joints, filling cracks, making sure insulation is adequate, or even waterproofing windows and roof glazing, there will be a product suited to your task. When it comes to DIY tasks, it’s important to make sure you use the right products. Soudal has built a reputation as an excellent manufacturer, meaning that you can rely on their products to perform as expected.

Choose the right Soudal product

Here at Edge, we have an excellent knowledge of Soudal’s product range. With years of experience providing customers with Soudal products, we know exactly what is required to help complete your project. When choosing products like Soudal’s sealants and adhesives, it’s important to make sure you have the right strengths for the materials you’re working with. So if you’re not sure which product to go for, feel free to contact us and speak with a member of our friendly team.

Bifold doors are a great way to introduce light and space into your project. However, if you’re not a window/ door fitter by trade, we’d recommend getting a specialist fitter in to do the job. They’ll need to ensure the doors are fitted securely, sliding, and folding smoothly with an overall sleek finish.

3 things to consider before fitting a bifold door:

-

- Check the building regulations – is the property compatible for a bifold door installation? Does your customer have planning permission?

-

- Consider the structural opening – Is it sturdy enough for the doors? Will the door opening withstand extreme weather conditions or burglary attempts?

-

- Check your measurements – make sure the measurements are correct to ensure the sliding and folding elements will be able to function properly.

Installation

So how do you fit bifold doors?

We’ve pulled together a full guide on how to fit bifold doors; this covers all stages of the installation: from delivery, assembling the outer-frame, removing the sashes, fitting the outer frame, refitting the sashes, glazing and toe & healing, and the final fixings.

If you would like to see our fully detailed and illustrated guide, please click the link below

Take me to the Bifold Installation Guide

You will either receive your door as a packaged assembled unit or you might receive your doors in kit form.

-

- Lay the outer-frame out on a flat surface and remove the packaging. Be careful to ensure that there is no grit or debris on the surface where you plan to lay the profile out. Once the pieces are laid out and the packaging removed put the top, bottom, right and left pieces of outer-frame roughly in position.

-

- Using the adhesive provided, apply to the inside of the outer-frame section, just passed both the punched out holes. Do this to each end of all the sections of outer-frame.

-

- Using silicone sealant, apply to the cross sectional faces of the profiles (see red area on the image to the left). Once applied, insert two cleats into each corner of the top and lower horizontal sections of outer-frame. The cleats are different widths; the wider of the two should be inserted to the door opening side and the narrower cleat to the rebated side.

-

- Once the cleats are fully inserted, position the chevron into the alignment slots as shown here in RED. Push the joints together. This is best done by fitting the left and right pieces of outer- frame to the bottom section followed by the fitting of the top piece.

-

- With the joint pushed together insert the cleat tensioning blocks into the four slots as shown. Make sure they are seated correctly before continuing.

Repeat this step for all four corners.

-

- Using a 2.5mm hex key, tighten each one in turn. You may find you need to slacken and re-tighten in order to make sure the joint is perfectly aligned. (This can be a bit tricky so take your time and don’t be afraid to slacken and redo if required.

-

- Make certain that all four cleat tensioning blocks are tight before moving on to the next corner.

Repeat this step for all the corners.

-

- Follow section 3 (Assembling the Outer-frame with a standard (DV14) Threshold) for the assembly of the top piece of outer-frame where it connects to the left and right hand sections.

For the low threshold section of outer- frame, apply silicone sealant to both sides of the end-caps and fit together as shown securing with the screws provided.

-

- After the two screws are tightened, the finished joint should look like the image to the left.

Once both sides are secure, clean down the joint.

-

- Removing the Sashes

For handling reasons, we recommend that the outer-frame is installed without the sashes attached. This is to make it easier for the fitter to position and fix the outer-frame accurately.

To remove the sashes, undo the five screws on one side of all four hinges for each sash. After the hinges are detached, the sashes with the roller and guide need to be tilted to be removed.

Fix any make up pieces to the door outer-frame at this stage ensuring a bead of silicone is applied to seal the joint.

-

- Fitting the Outer-frame

If your door comes with a sill, fix it to the outer- frame before positioning it into the aperture. If you have opted for no sill then position the outer-frame into the opening.

Using a spirit level and tape measure, pack every 300mm around the outer-frame making sure it is level and plumb. Use a tape measure to check the diagonals are equal to ensure the outer-frame is square and use a plumb line to check all the sections of outer-frame are straight and not bowed.

Position the packers either side of the fixing screws so when tightened it doesn’t pull the outer-frame and distort it.

-

- Once the door outer-frame is plumb, level and square, fix to the surrounding brick work. We recommend you fix through the thermal break using concrete screws.

-

- Refitting the Sashes

To refit the sashes, position each sash in turn into the outer-frame and re attach using the hex head machine screws and the central self tapping screw

For the glazing and Toe & Healing, please refer to pages 9-15 in our installation guide

-

- Final fixings & Magnetic Catch

After you have toe and healed each sash and checked the operation, you will need to fit the glazing beads. To do this replace the beads in the same order they were removed and secure by fitting the glazing tear off gasket supplied.

-

- To stop the traffic door from swinging in the wind when open, there is a magnetic catch; supplied. Following the instructions in the magnetic catch box, install one half 165mm in and 30mm down on the top of the opening end of the traffic door. Install the other half in the same manner on the sash next to the traffic door so when fully open the two halves connect as shown opposite.

Not FENSA registered?

Fitting bifold doors can be tricky, and if it’s not done properly, can often lead to problems with locking, sliding, folding or even weatherproofing. This is why we do recommend that you hire a trained, experienced professional to measure and fit your bifold door if you are not FENSA registered yourself. They will know what considerations are needed and the fitting tolerances to cater for.

We have a few recommended fitters up our sleeves, so give us a call if you would like some more information.

Our bi-fold doors

At Edge, we specialise in both the aluminium bifold by Smarts, namely the Visofold 1000 Range, and the Aluminium bifold doors by Origin. We find that both products are extremely good quality and can suit any project.

If you would like a quotation for one of our bifold doors, a fitter recommended or some additional information about bifolds, please email [email protected] or head over to the aluminium bifold web page.

The September installation of the month is awarded to Grover Building Services for their installation of Origin aluminium bi-fold doors and Smarts aluminium windows at this beautiful Surrey residence. This stylish outbuilding comprises a double garage, gym and mezzanine office space which has been wood cladded to remain in keeping with the rest of this stunning country setting.

Large expanses of glass and a slim aluminium profile create a feeling of space and light in the building providing a completely uninterrupted view when open, and giving the homeowner the flexibility to enjoy their indoor and outdoor space as one.

The apex windows above the bi-fold doors give a contemporary feel to this stylish outbuilding, creating a bright, airy feeling throughout.

The homeowner was delighted with the service she received from Edge, saying “the customer service was excellent and the attention to detail was first class”.

Grover Building Services have done a fantastic job here and we look forward to seeing more of their work in the future.

Please contact us to discuss your bespoke glazing requirements 0345 021 3333 [email protected]

My Basket

My Basket