Flashing is an important element in the weatherproofing of buildings, and in this Quick Guide to Flashing, we explore the most common types of flashing material, how it is used, and our product recommendations, to help you make an informed decision about which flashing is right for your clients’ projects.

Weatherproofing is the process of making a structure resistant to the elements and can be achieved through many forms. It is a vital element of a building’s sealant as it helps to prevent water damage which can lead to mould growth, wood rot, and severe structural issues. It can also help to reduce heating and cooling costs by preventing drafts, and this is particularly important with the recent steep rise in fuel bills. There are many different ways to weatherproof a building, but in this guide we specifically put our focus on Flashing.

What is ‘flashing?’

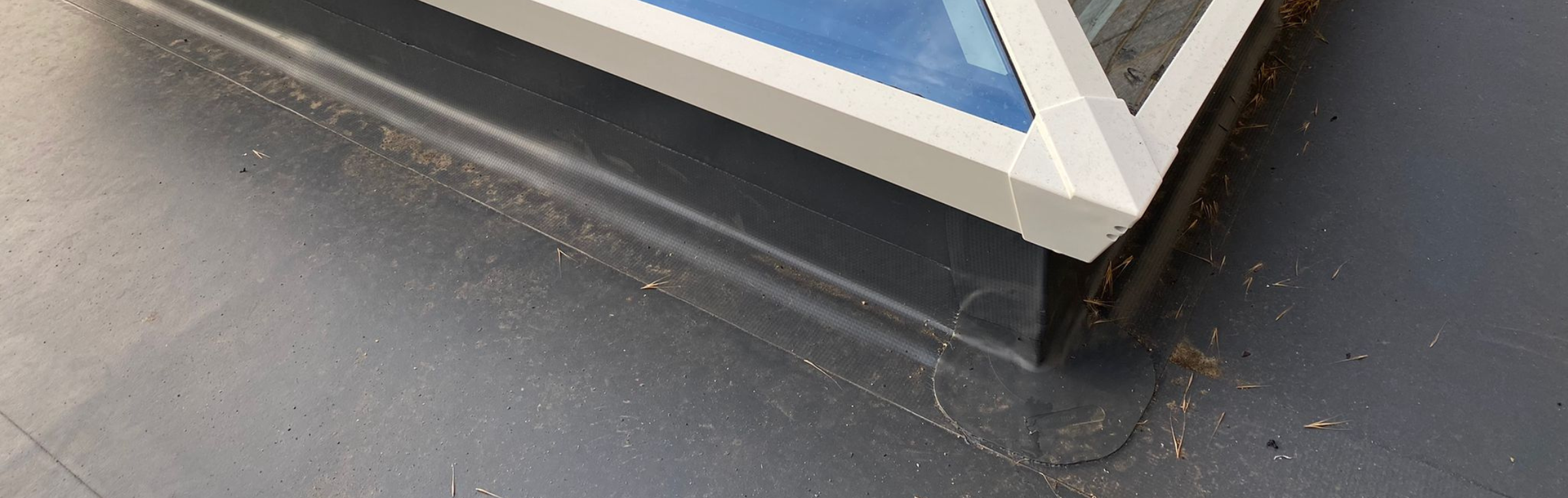

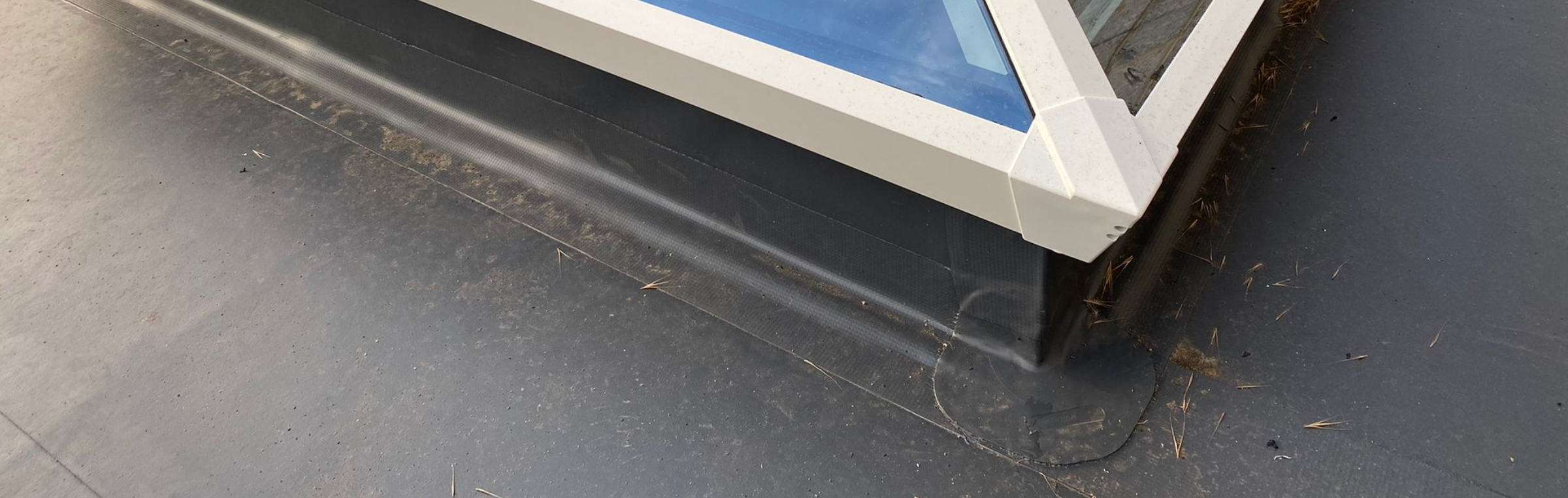

Flashing (sometimes referred to as “seaming tape”) is used to seal and protect areas of a building, (the building “envelope”), where two pieces of material meet, such as at roof edges, corners, chimneys, around windows, doors, and vents. Flashing is so important because it prevents water from penetrating the building envelope, which can go on to cause serious damage. When installed correctly, weatherproofing flashing can help to prolong the life of a building by decreasing the chances of this water penetration.

There are several different types of flashing available, each with its own advantages and disadvantages. In this guide, we will take a look at the most common types of flashing so that you are able to make an informed decision about which one is right for your project.

Types of flashing

The most common types of flashing are metal flashing, and the more modern alternative – flexible flashing.

Metal flashing can be made from galvanized steel, lead, copper, zinc or aluminium and is typically installed using nails or screws. There are advantages of metal flashing which include its long-term durability. Copper, a popular choice for flashing, is relatively pliable and can be soldered, but it comes at a high price. Aluminium on the other hand can be painted, if required, for a more aesthetically pleasing finish. It is also slightly cheaper than copper, but it is less pliable. Aluminium flashing would also need to be joined to the roof by stapling or by using another mechanical fastener.

The disadvantage with all metal flashing is its susceptibility to corrosion. It can also be more difficult to repair than other materials if it becomes damaged. Often, whole strips of the metal flashing will need to be replaced which, of course, can be a costly and timely process.

Flexible flashing products are asphalt-based, self-adhered membranes, which are applied to the surface of the building with an adhesive backing which is protected by a peel-away release paper. Flexible flashing is available in a variety of widths and lengths and can often be customised to fit most building projects.

The advantages of asphalt-based, self-adhered flashing, include its flexibility, durability, its convenience, and its ease of installation. One of their very few disadvantages of flexible flashing is that it may not have the lifespan of their metal counterparts. Still, they are increasingly popular because of their simple application. Unlike metal products, they are also a more economical option, which is often an important consideration when it comes to building or home improvement projects.

At Edge Building Products, we sell the Butyl Flashband (flexible flashing) product. Butyl flashings are made from butyl rubber and they’re extremely popular due to their ease of application in cold weather, (perfect for building projects carried out during harsh UK winters!). They also bond a little slower, which helps with any adjustments needed during the installation process.

Our butyl flashband is a rubber-based sealing tape which provides a fast and excellent adhesion to many substrates. As well as its flexibility even in cold temperatures, it is UV and weather resistant, meaning it is excellent at keeping moisture out. In addition to being a perfect solution for sealing around chimneys, air vents, sky lights, windowsills and sliding doors, our butyl flashband is perfect for repairing areas where previous membrane has worn away. This means it’s a perfect solution for patching up areas that need it, rather than having to replace the entire flashing.

We sell butyl flashband in 3 different widths, 150mm, 225mm, and 300mm, all in rolls of 10m. The Lead Grey finish means it is ideal for use in most flashing applications. Butyl flashing can be purchased from any of our trade counters in Chichester, Horsham and Croydon, where we supply high-quality products to the building trade.

Whichever trade counter you choose to visit, we will always ensure you are given the best advice and support needed.

Still have questions about our weatherproofing flashing products? You can contact us at [email protected] or telephone 0345 021 333.

My Basket

My Basket